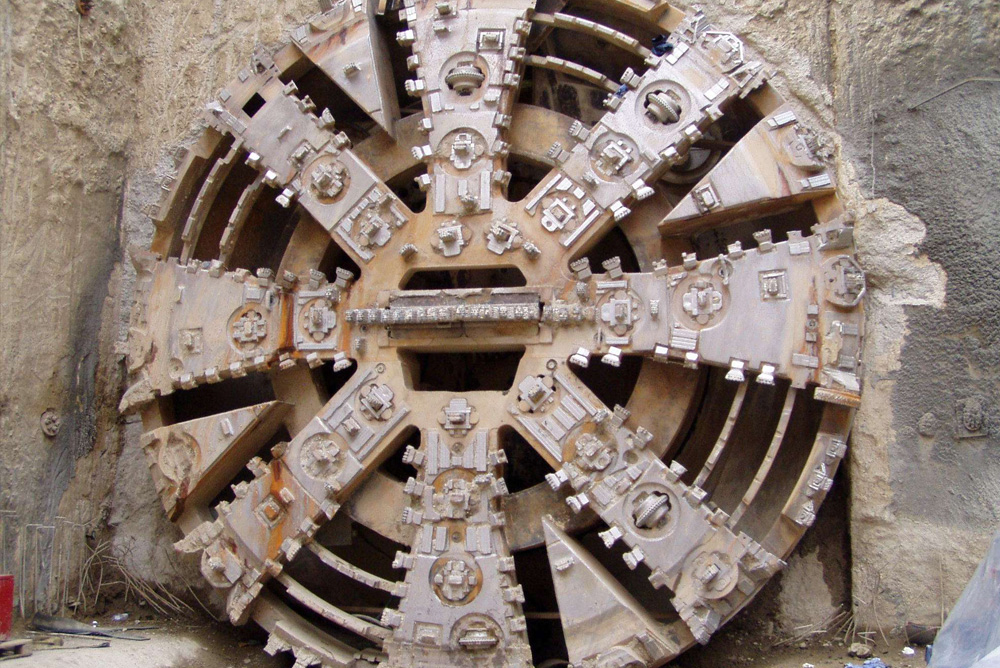

The best cutting tools for your TBM!

Innovation. Experience. Quality.

TunnelTec GmbH is a globally successful supplier of exceptionally durable and efficient cutting tools for tunnel-boring machines (TBM). As a full-service supplier, our cutting tools deliver, tool concepts and expertise solutions meet the challenges of mechanized tunnel-heading operations and assure convincing added value for our customers:

1. Long heading lengths with no tool changes

2. Constant high advance rates

3. Significant cost-savings

For close on twenty years now, we have been convincing our customers with our individualized and innovative technical solutions. Our customers’ tunneling sites benefit every day from our many years of experience, especially in the development of perfectly tailored tool concepts for soft-ground TBMs. And our high quality sets totally new standards.

Talk to us about cutting tools! We’ll be pleased to help your project succeed.

Dipl.-Ing. Markus Allwicher, Managing Director

Cutting tools, the critical interface between the machine and the ground, play a role of the utmost importance. This is why the development of a cutting tool concept specially tailored to your particular project will assure time-savings, lower costs and greater planning certainty for the tunnel-heading phase. Our direct contact with your site and equitable cooperation with your personnel are sure to enhance your project’s overall success.

TunnelTec cutting tools achieve high advance rates with significantly longer tool lives for your TBM. Downtimes are reduced or even eliminated, with the result that you are able to attain your targets and milestones on time – or even ahead of time!

Innovation is our strong point!

Our innovative tool concepts and project-specific cutting tools developed for soft soils assure solutions for demanding challenges in your tunnel-engineering projects, signifying lasting competitive advantages thanks to cost reductions.

We react fast to the new requirements and changing conditions as tunneling progresses and immediately modify our concepts or refine them further. If you find limitations in advance rate or tool life in the cutting tools you use, we will be pleased to develop for you an individualized solution that will eliminate these and similar shortcomings.

Our target is always to attain the greatest possible efficiency and cost-effectiveness for your project.

We are not tied to any machine manufacturers and are thus able to develop for your project the best solution using totally new and innovative concepts.

We support you in overcoming new and difficult challenges on both ongoing and future projects, and thus aim to make an important contribution to the success of your projects.

At the same time, our innovative solutions and cutting tool concepts facilitate further technical development, contributing to lasting improvements in the efficiency of tunnel-heading work.

We’ll find the right innovative solution for you!

Our years of experience put us ahead!

We have been overcoming challenges on tunnel-engineering sites around the globe since 2004. Our experience provides the basis for our efficient and multiply tried-and-proven solutions, which are especially valuable on tunnel-engineering projects confronted with demanding ground conditions.

We recognize and solve problems before they arise and immediately take the necessary action. The cutting tools which we develop are known for their long service-lives and the resultant economic efficiency. We know that homogeneous and optimized wear behavior in the entire cutterhead is a decisive factor for you when selecting cutting tools. The experience gained from our worldwide projects is incorporated into new developments. We are working continuously on reducing the primary wear of our tools, enabling us to achieve ever longer tool lifetimes. Stops, ground consolidation and man-entries (frequently by divers) can then be reduced or even totally eliminated. Another important factor in boosting cost-efficiency is the reduction of secondary wear. This is why our cutting tool concepts for your TBM are oriented around improving material flow at the cutterhead and around minimizing or even eliminating repairs.

Intensive interchange with our customers shows just how important the topic of risk minimization is. Critical items include, for example, interruptions for tool changing – as already mentioned – and the possible necessity of repairs. In addition, ever greater importance also attaches to the hazard of ground settlements and overcut, particularly in the case of soft-ground TBMs. Our experience, analysis of the ground and the resultant cutting tool concept provide at this point the vital basis for low-risk tunneling. We create pragmatic and practicable solutions – as we have for nearly twenty years.

A decisive lead!

Our high-quality tools are the basis for your success!

As a manufacturer of high-quality cutting tools for tunnel-boring machines (TBMs), we know precisely our customers’ requirements and expectations on our tools. Dependable, high-quality products assure cost-efficient advance rates that remain constant across long tunnel headings.

To live up to our standards, our experienced team accompanies and supports every individual stage of production, from the initial concept through to the finished product. Every operation in the making of our tools is completely recorded and monitored under a detailed Quality Assurance regime. This enables us to assure that every single tool makes an optimum contribution to the tunneling process and to guarantee simple, clear, accurately-fitting installation.

In selecting our suppliers for feed materials and products, we attach special importance to reliable and diversified supply chains and to consistently high-quality materials. This strategy assures constant supply capability backed up by constant high quality standards.

During the design phase, we devote special attention to the functionality, reliability and service-life of our tools. The optimization that we achieve rewards our customers with exceptional cost-effectiveness and efficiency during tunneling.

Our modified and individually developed tool concepts enable you to tunnel further, more efficiently and faster. The changes necessary to the cutterhead can be implemented easily and quickly using our all-inclusive documentation, featuring all relevant drawings and detailed information of proven practical usefulness.

Quality pays off – every time!

Our focus is always on the success of your project!

For our team, this guiding principle is no empty promise. To assure the success of your project, we develop the best cutting tool concept and produce best-quality tools. Every day, we tackle the challenges that confront our customers and are glad to be measured by their success.

1. Long tunnel-heading lengths with no tool changes

2. Constant high advance rates

3. Significant cost-savings

4. Technical support during tunneling

5. Direct communications and equitable cooperation